Gason Air Seeder Retrofit Double Discs & Coil Press Wheels: Adrian Burke’s Experience in Finley, NSW

In the southern Riverina of New South Wales, Adrian Burke has been using RYAN NT Retrofit Double Discs and Coil Press Wheels on his Gason Air Seeder for three planting seasons. As a first-time user of press wheels, Adrian shares how this combination has revolutionized his seeding operations for crops like vetch, wheat, canola, and rice.

Enhanced Seed Placement and Soil Contact with the Gason Air Seeder

For Adrian, the transition to RYAN NT discs and press wheels marked a significant improvement in seed placement and soil contact. “The seed placement [with the discs] on this machine seems to be a lot better than tynes,” Adrian explained. The addition of press wheels, which he had never used before, further enhanced the results. “The press wheel seems to be making a big difference as well.”

The Coil Press Wheels are designed to self-clean and press air out of the soil around the seed, ensuring optimal seed-to-soil contact. This design promotes faster and more even germination compared to traditional systems. Adrian noted how these innovations have allowed him to achieve consistent results across multiple crops and conditions.

Coil Press Wheels are ideal for no-till and reduced-till operations, where maintaining the soil structure is crucial. Their spring coil design ensures they remain functional in challenging conditions, even in heavy residue.

Adrian Burke with his Gason Air Seeder fitted with RYAN NT Retrofit discs

Precision in Rice Planting Due to Discs on Gason Air Seeder

Adrian has been using the discs to plant rice. Describing the precision of the setup, he explained what he liked about the discs, which was the “Nice, neat little ridge for the drill-sown rice to sit in.” Emphasising that when the water fills the ridges after planting, the seeds germinate effectively. This approach minimises soil disturbance while maximising planting efficiency.

The RYAN NT Retrofit Double Discs are engineered for minimal disturbance planting. Unlike tynes, which can tear through the soil, the double disc design ensures a clean cut and a well-formed seed trench. This precision is especially valuable in crops like rice, where seed placement and water infiltration are critical.

Adrian Burke's Gason Air Seeder Retrofit Discs

Reliable Performance Over Three Seasons

Adrian adopted the RYAN NT Retrofit Double Discs on his Gason Air Seeder in 2023. Since then he has covered approximately 4,000 acres without replacing any disc hub bearings. “No bearings at 4,000 acres roughly,” he shared. This durability has minimised maintenance costs and downtime, enabling Adrian to focus on achieving high-quality planting results.

The discs have also proven effective in various crops, including vetch, wheat, and canola. “Performed really well in all of them,” Adrian said, underscoring the versatility and reliability of the RYAN NT system.

Farmers seeking to enhance their seeding equipment while minimising costs are speaking to RYAN NT. This is because retrofitting is a cost-effective alternative to purchasing new machinery. For Adrian, this approach not only extended the life of his Gason Air Seeder but also significantly improved its performance.

Adrian Burke's Gason Air Seeder Coil Press Wheels

Smooth Handling and Versatility on the Gason Air Seeder

Adrian’s Gason Air Seeder bar, fitted with RYAN NT equipment, operates smoothly even when turning in the field. While he avoids sharp turns in tight ground, he noted, “In worked ground, I do [turn around corners].” This adaptability shows the robustness of the discs.

Adrian highlighted the system’s ability to handle wet conditions. Acknowledging that he would only switch back to tynes if absolutely necessary. Adrian emphasised he most likely would not switch back by saying, “If it’s too wet for these discs, it’s too wet for this bar.”

In no-till and reduced-till systems, maintaining the integrity of the soil while ensuring efficient planting is critical. The Double Discs‘ ability to cut through residue and plant with minimal soil disturbance makes them an essential tool for these farming practices.

Adrian Burke's Gason Air Seeder Retrofit Discs Working

Cost-Effective and Durable Solution

For Adrian, the investment in RYAN NT Retrofit Double Discs and Coil Press Wheels has delivered significant value. The system has enhanced planting precision and reduced maintenance requirements. The press wheels' self-cleaning design and the discs' durability have allowed him to achieve high productivity with minimal upkeep.

This combination of durability and performance makes the RYAN NT system an ideal upgrade for farmers. Farmers seeking to modernise their existing equipment can now do it without breaking the bank. By retrofitting the Gason Air Seeder, Adrian avoided the need to purchase an entirely new seeder. Ultimately, this choice saved him significant time and money.

Adrian Burke's Gason Air Seeder Retrofit Discs Working

Word from the Company

The team at RYAN NT is proud to support farmers like Adrian Burke in achieving consistent results with innovative and reliable equipment. “Adrian’s experience demonstrates how our retrofit double discs and coil press wheels work seamlessly together to deliver superior seed placement and germination,” said a company spokesperson. “We’re committed to providing cost-effective solutions that enhance efficiency and reliability.”

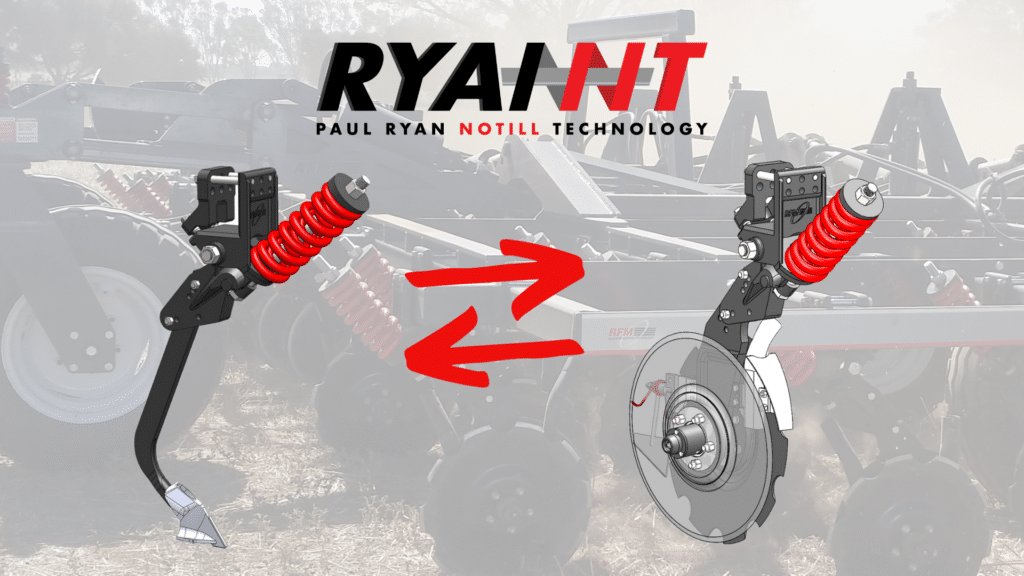

RYAN NT Retrofit Discs – Tyne to Disc Conversion

Learn More About RYAN NT Retrofit Double Discs & Coil Press Wheels

Looking to upgrade your equipment like Adrian? The RYAN NT Retrofit Double Discs and Coil Press Wheels are designed to work together for precision planting and optimal germination. Learn more:

Conclusion

Adrian Burke’s story highlights the transformative impact of the RYAN NT Retrofit Double Discs and Coil Press Wheels on modern farming operations. From enhanced seed placement to durable performance across multiple seasons, these tools have become vital to Adrian’s seeding system. The RYAN NT system offers a proven, reliable solution for farmers seeking to optimise planting precision, improve germination, and reduce maintenance costs.